Form

-

Maximum Instant Storage Capacity

3,210 tonnes (450 tonnes in liquid waste tanks, 140 tonnes in sludge or solid waste tanks) -

Treatment capacity

25,000 t/year of hazardous waste. There are no restrictions on non hazardous waste -

Accepted waste

special and municipal waste, hazardous and non hazardous. -

Disposal codes

Technology

How does the plant work?

The plant consists of the following sections: storage area, processing rooms, grinding plant, inerting plant.

Specific waste control procedures are applied both when contracts are drawn up with customers (approval phase) and when disposals are received at the centre. Correspondence between the quality of the incoming waste and the respective approval is verified by means of visual and analytical checks carried out periodically and spot sampling the waste. Following the control phase, waste is labelled and stored in the centre's facilities, waiting to be treated, repackaged and sent to external disposal plants.

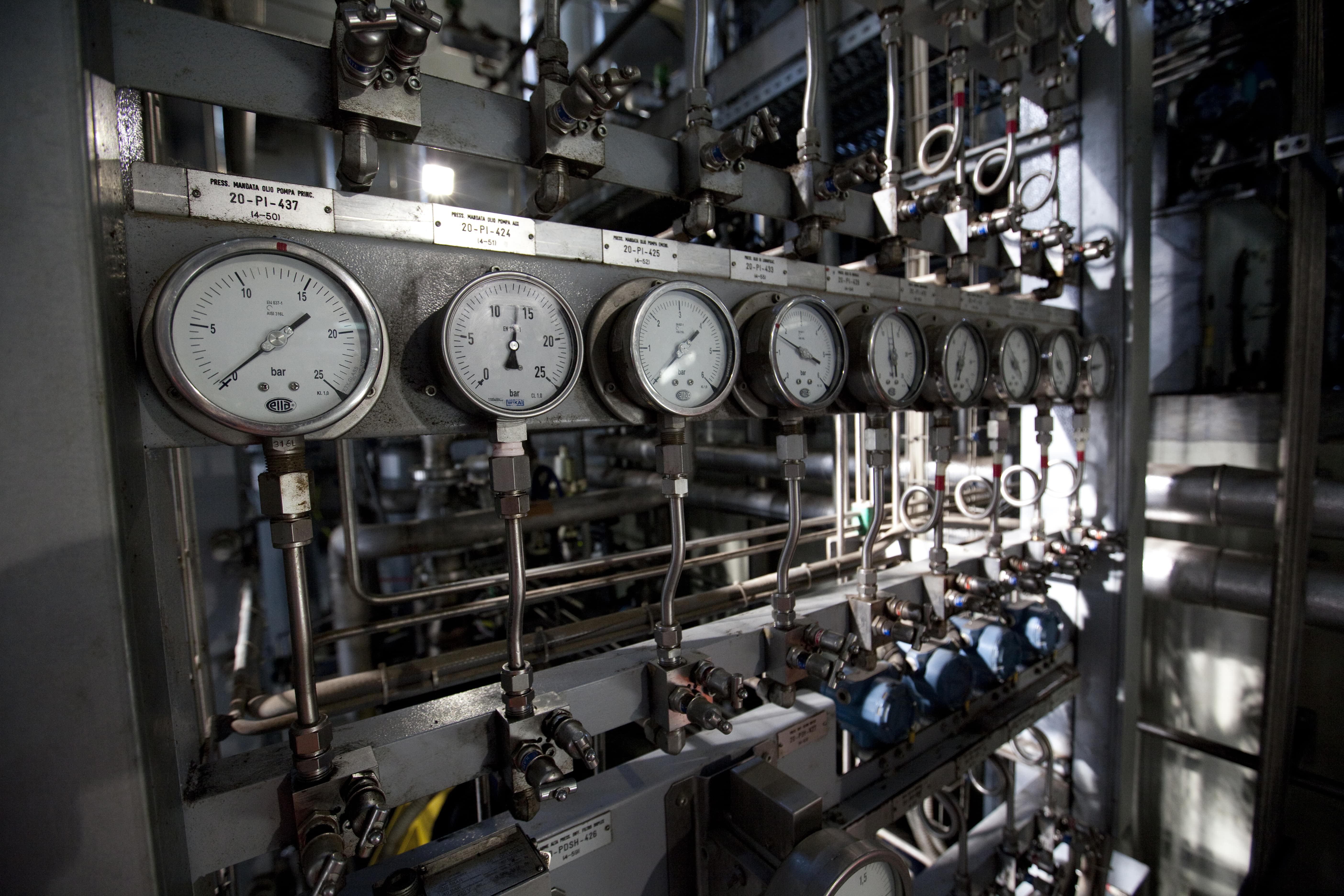

Waste in small drums or containers is stored in separate departments depending on the different characteristics in terms of danger and flash point, in order to ensure maximum safety for the entire area. The various types of waste are stored in suitable containers (steel tanks, silos and reservoirs) and all handling (unloading and transferring) is carried out using steel pipes and pumps, while the gaseous fumes generated are channelled to an activated carbon purification system. Waste accepted for storage may be sent for pre-treatment, for example: repackaging of solid waste including powdery waste; repackaging of liquid waste; repackaging of two-phase waste; mixing and homogenising; thickening; waste compaction (in a permanent grinding plant). All treatments are carried out in rooms with a sealed floor, which are confined and maintained under vacuum, with dust extraction of the aspirated air and subsequent passage through activated carbon filters. Specific sensors detect the presence of any traces of flammable gases.

The compacting of hazardous and non-hazardous solid and pitch-like waste is carried out in a confined building with a sealed floor, in order to prepare it for final disposal. Contaminated empty packaging may also undergo such treatment. The grinder is fed by a fixed, orange peel grab device remotely controlled by an operator in an elevated position for visual control and isolated from the surrounding environment.

The rooms are equipped with suction tools, flammable gas detection sensors and a specific foam fire-fighting system.

The rooms are equipped with suction tools, flammable gas detection sensors and a specific foam fire-fighting system.

Due to the hazardous substances that may potentially be found in the incoming waste and the related maximum quantities allowed, the Centre is a facility at risk of major accidents, subject in particular to the provisions of Articles 13 (Notification), 14 (Major Accident Prevention Policy) and 15 (Safety Report) of Legislative Decree No. 105/2015, as amended, therefore it has implemented a specific Safety Management System for the control of major accident hazards.