Let's give a new lease of life to waste

We collect municipal and industrial waste and process it to create new secondary raw materials such as paper, plastic or biofertilisers. Thanks to our know how and a range of specialised facilities, we can regenerate waste and turn it into a new resource. We cater to the utilities and corporate market by maximising material and energy recovery, putting recovered materials back into the production cycle or by producing biofuels, sustainable fertilisers and high quality recycled polymers. Finally, the non recoverable fractions are transformed into electricity to reduce the amount of waste that is sent for landfill.

Our figures speak for themselves

We manage millions of tons of waste every year, committing to reduce it and turn it into a new resource with a circular economy approach.

*2024 data

-

162 ktonnes/year paper or cardboard sent for recycling/recovery

-

160 ktonnes/year plastic regenerated and sent for recycling

-

110 ktonnes/year glass sent for recycling

-

80 ktonnes/year wood sent for recycling

-

41 ktonnes/year compost produced for agriculture

-

220 ktonnes/year bottom ash to recovery

-

49 ktonnes/year dust to recovery

-

4,3 ktonnes/year iron to recovery (extracted from slag)

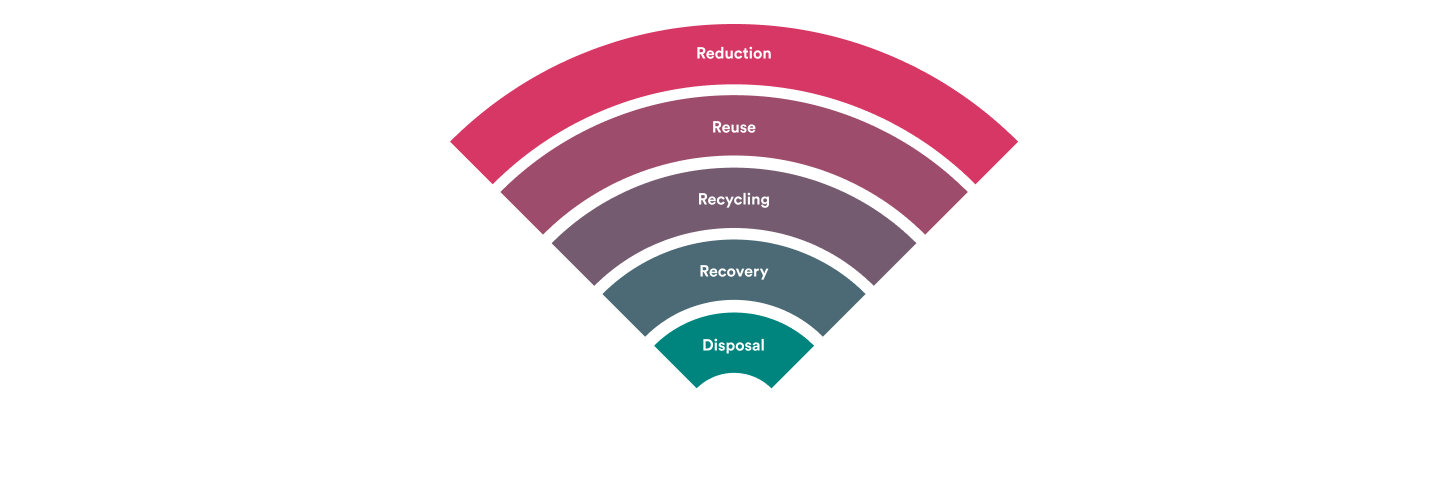

Responsible management under the perspective of the circular economy

In the management of waste collected from companies and local communities we embrace the circular economy strategic approach promoted by the European Union, optimising and preparing them for recycling. We transform what cannot be recovered into energy through our WTE/Waste to Energy plants for municipal, special, solid and liquid waste. To create a circular economy, we also need to close the circle of responsible, safe and traceable waste management, which is why we only send non recoverable fractions for landfill. We send less than 2,5% of municipal waste to landfills, exceeding the EU Directive's goal of falling below 10% by 2035.

The valorisation of organic waste is a concrete example of closing the circle

In our 6 composting plants we treat organic waste using its natural decomposition process to create fertilisers, closing a virtuous cycle that begins with the separate collection by citizens of mowing of lawns, pruning and organic waste. The products we obtain are natural soil conditioners that have obtained the quality label issued by the Consorzio Italiano Compostatori (Italian Composters Consortium). Thanks to our work, waste becomes a starting point for producing compost, but also energy, heat and biofuels.

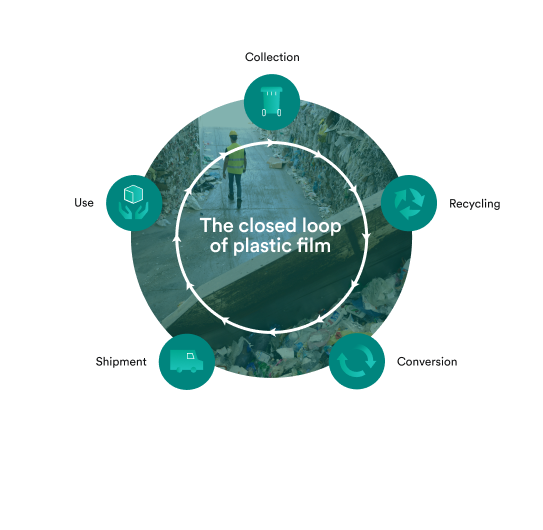

Our virtuous circle of plastic

Through Aliplast, a subsidiary of the Herambiente Group, we can complete and close the circle of plastic waste management, taking care of all the phases: from the collection of packaging and other plastic waste, to its regeneration, to the production of new material to be reintroduced into the production cycle. The finished product is a quality material equivalent to virgin plastic, which can be processed into flexible PE films or thermoformed as required.

For local communities

Discover all our solutions designed for local communities.