Assigning value to the environment to add value to businesses

Choosing to invest in advanced recycling systems following the logic of the circular economy is a sign of respect towards the planet, which allows companies to do their part for a sustainable present and future, but also to save money. A virtuous example of this is the partnership between Aliplast, a Herambiente Group company specialising in the production of regenerated plastics, and Panariagroup, a company with a long tradition in the ceramics industry based in Finale Emilia, Lower Modena.

Together for the recovery of plastic waste

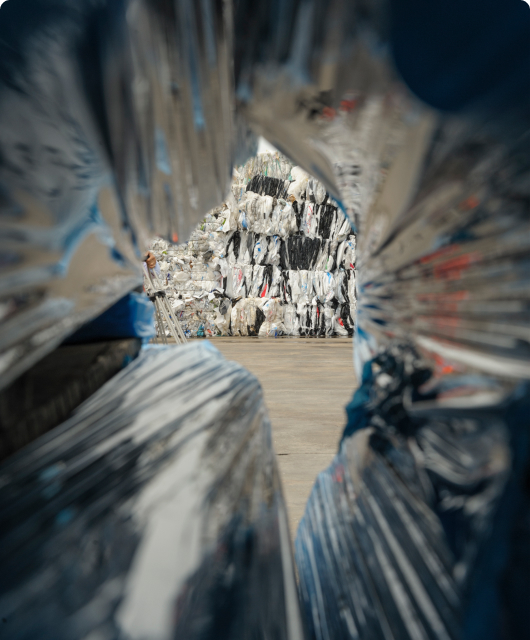

Panariagroup, which has been producing and marketing high-quality porcelain stoneware floors and wall tiles since 1974, is strongly committed to sustainability and has been producing a non-financial statement since 2016. Panariagroup uses low-density polyethylene shrink wrapping film to wrap the pallets produced during the different processing phases; the tiles are packed several times according to a procedure that results in the use and disposal of large quantities of packaging material.

To recover the material and build a virtuous circle of reuse and recovery Panariagroup has relied on Aliplast. Together, they have developed a system that first selects and reduces the volume of the waste material directly on site, and then sends it to the Aliplast centre, where it is transformed into granules and then into new packaging film, ready to be reintroduced into the Panariagroup production cycle.

The project started in 2005 in one of Panariagroup's plants and since 2010 has been extended to all the ceramics production plants that are part of the company.

Closed loop: a winning approach

The recovery of waste within the Panariagroup factories, is done by following the closed loop: a recovery logic aimed at maximizing sustainability that involves the recovery of plastic waste, its treatment and regeneration to obtain a quality product, with technical characteristics equal to those made from virgin material, ready to be fed back into the production cycle.

The results

The partnership between Panariagroup and Aliplast has led to concrete and tangible results with a positive impact on both the environment and on the costs for the company, which saved money by purchasing regenerated material instead of virgin material.

-

95 % material recovered

-

450 t/CO2 avoided

You may also be interested in...

Discover more..