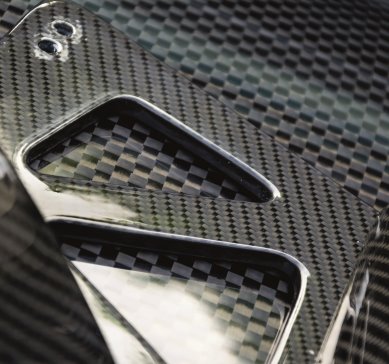

Carbon fibre given a new lease of life in the Motor Valley

One of the first plants in Europe capable of recycling carbon composite materials could only rise near the Imola Circuit (officially called the Autodromo Internazionale Enzo e Dino Ferrari).

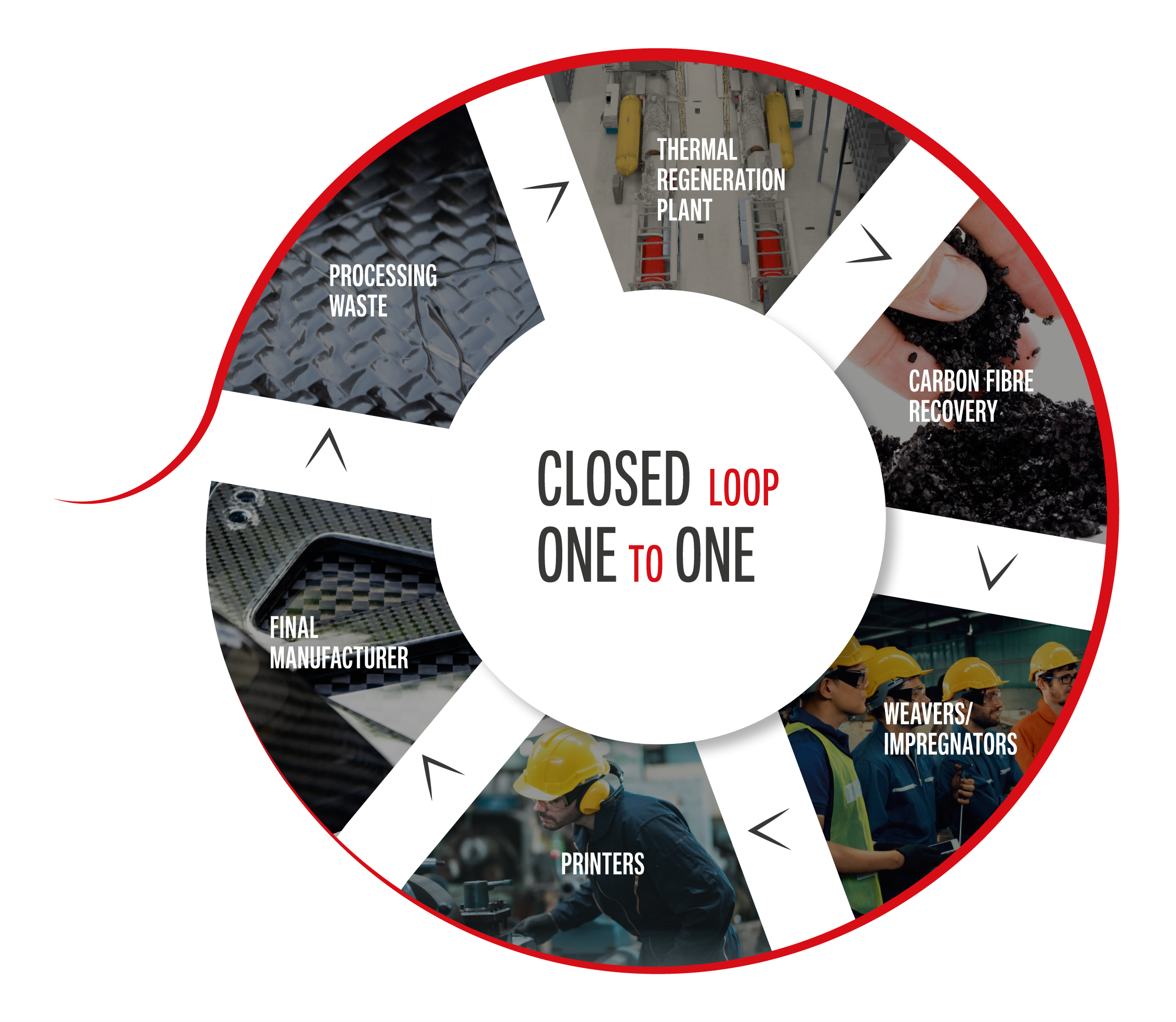

In Imola, the precious fiber is freed from resins and additional additives during molding and forming and is ready to be reused in a potentially infinitely repeatable cycle, keeping intact its well known characteristics of light weight and high strength.

An innovative solution that meets the needs of various target industries: from automotive to aerospace, as well as nautical, construction, furniture, textile, wind power and composite material processing.

An innovative plant serving the environment

Operational since 2024 has obtained under the NRRP a contribution from the European Union, thanks to the Next Generation EU program.

The plant owned by the Herambiente Group is the result of an important three-year trial carried out in collaboration with the Toso Montanari Department of Industrial Chemistry of the University of Bologna and its technological partner Curti, a leading manufacturer of automatic machines for industrial applications.

The industrial-scale construction of the plant has been started and this will be operational from 2024, precisely because of the innovativeness of the technology used and the strategic relevance of the materials involved the project has also obtained an EU contribution.

A process under the sign of the 3 R's

Recover, Reduce, Reuse Carbon Fiber: for virtuous recycling that reduces the impact of manufacturing activities.

Recovering is the process of collecting and treating materials such as carbon fiber into new product through thermal regeneration. It is a way to give waste a new life instead of sending it for disposal.

Reduce means using less, decreasing waste production from the very beginning of the supply chain. Preferring recycled carbon fiber is a first step toward that goal.

Reusing means giving a second life to materials, in this case waste.

We turn your waste into resources

Join Herambiente as a partner, entrust us with the management of your carbon fiber composite waste

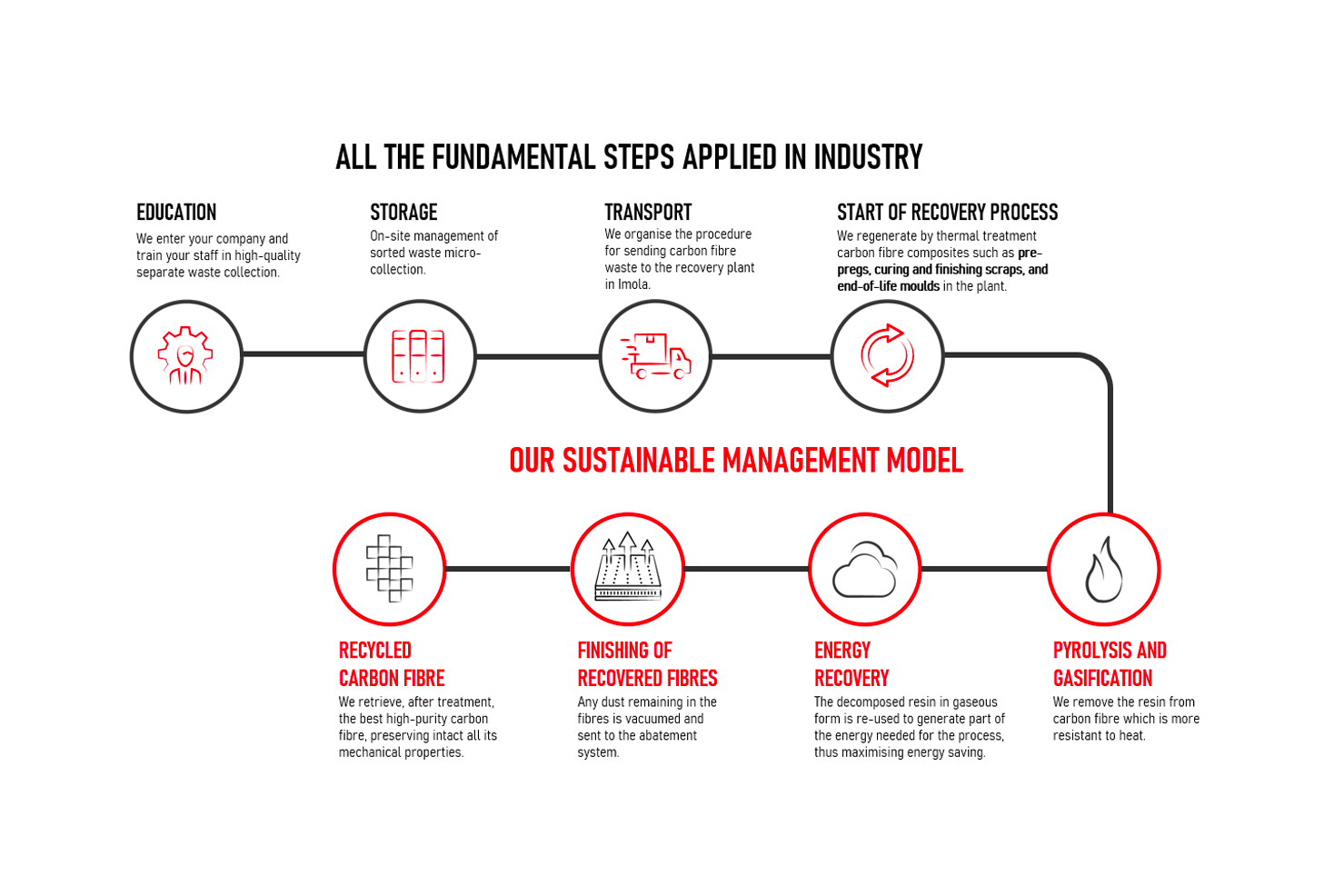

For your company, choose the reliability of Italy's leading industrial waste management operator; by delivering your impregnated or cured scrap, molds, off-spec and end-of-life composite products to us, you enable quality recycling, reducing landfill deliveries and your company's impact on the environment. We take care of everything, from collecting waste and scrap directly at your company with specialized means and methods, to training your staff, all in the utmost safety.

Contact us

Recycled fiber: the ideal solution for your industry

Buy our top-quality, fully sustainable and environmentally friendly regenerated carbon fiber

The carbon fiber we produce can be rewoven and impregnated for all the typical uses of virgin fiber, for autoclave, press and molding processes: nonwoven fabric, patchwork, carbon milled, short fiber, smc and bmc, and more. Herambiente's recycled fiber provides excellent mechanical properties in line with virgin fiber: elasticity, strain and extension at break up to 95%.

Contact us

We help you close the sustainability loop

Our processes are tailored to meet your company's needs and guide it through the ecological transition in line with the principles of the circular economy.

By controlling the supply chain, we can ensure maximum sustainability of the production process for our clients. A fully traced supply chain guarantees transparency and quality to the entire process: from the collection of waste materials even from subcontractors to the treatment, up to the return of recycled carbon fiber to the company, ready to be processed again.

Why should you choose recycled carbon fiber?

Our processes are tailored to meet your company's needs and support it in the ecological transition in line with the principles of the circular economy.

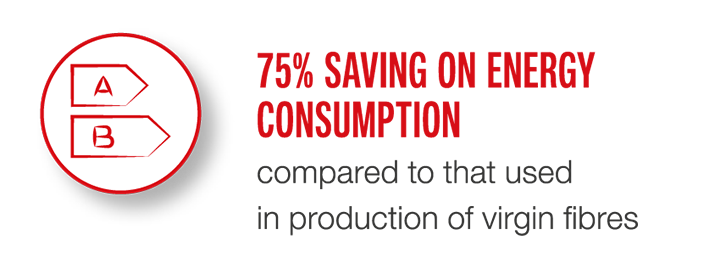

The production process of virgin carbon fiber from pitch or PAN (polyacrylonitrile) is highly energy intensive due to the high temperatures used, uses fossil raw materials, and fiber processing waste is almost exclusively for disposal. Life Cycle Assessment (LCA) analysis shows that energy demand for recycled fiber production is 75% lower and avoids 74% of greenhouse gas emissions, significantly reducing landfilling. A great way to actively contribute to reduce your company's impact on the environment.